Magellan Aerospace has demonstrated expertise in the manufacture of hot section components for civil, industrial, and military engine platforms. Our products are manufactured through various fabrication, machining, and treatment processes, primarily on hard metals, to yield the highest quality products for our customers in their most critical operating environments.

Engine Hot Section

Products

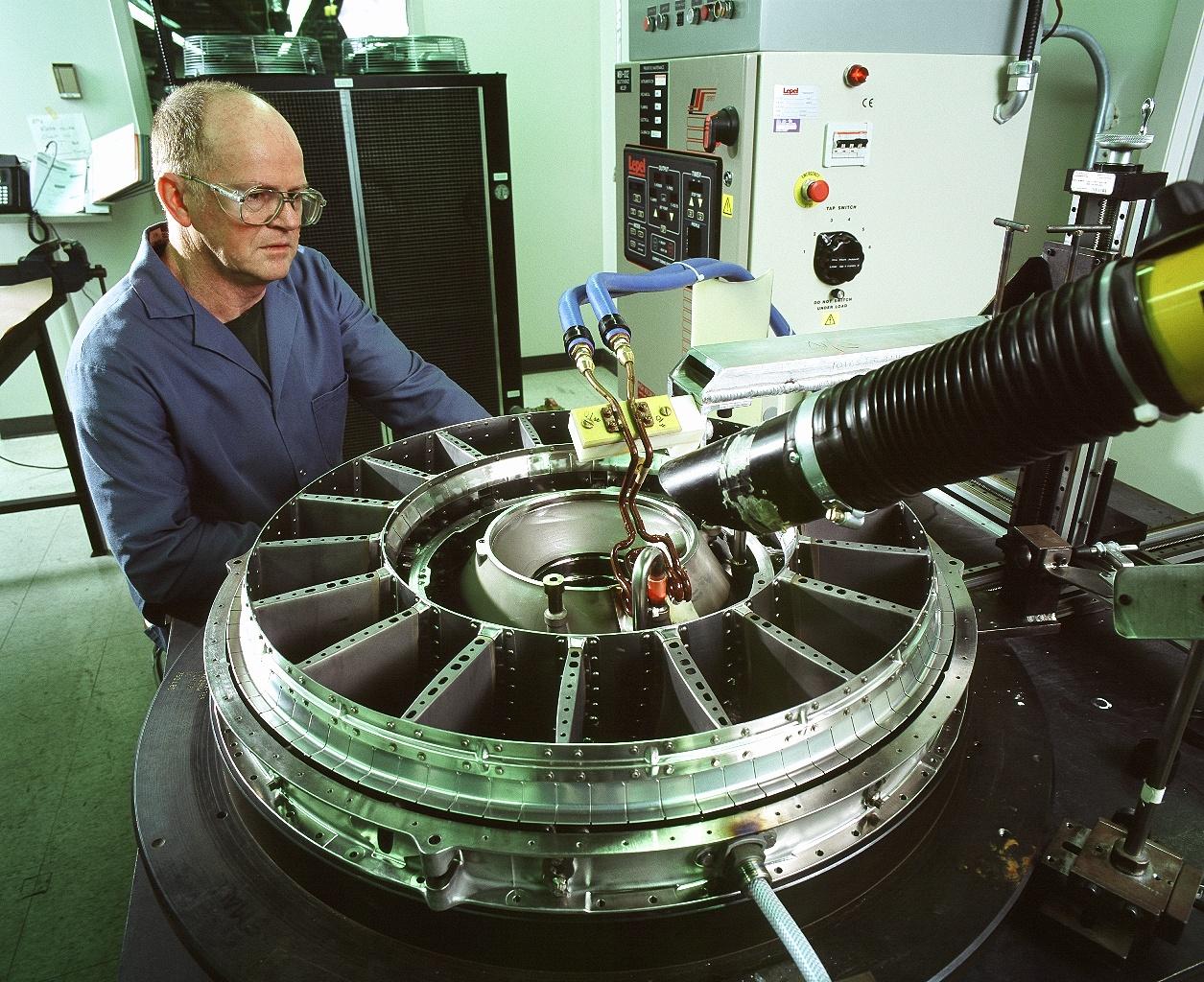

FRAMES and CASES

Magellan manufactures a variety of frames and cases for use in the engine hot section. They are typically nickel-based alloys manufactured from casting, forging, bar, and sheet metal. We are known for producing high quality details and large complex assemblies.

Details:

- Up to 78.7” dia (2.0m)

- Full NC turning and 5-axis milling

- Complex sheet metal fabrication and assembly

- NADCAP approved chemical processing in house (multiple)

- NADCAP approved vacuum and atmospheric heat treatment in house

- NADCAP approved welding and brazing (multiple)

- NADCAP approved non-conventional machining (laser, waterjet, EDM)

- NADCAP approved NDI (X-Ray, C-Scan, LPI, eddy-current)

F414 R&O Induction Brazing

Turbine Components

Controlled broaching is a unique and key element in Magellan’s manufacture of turbine components, which require extremely tight tolerances with zero surface anomalies. We also offer maintenance solutions to our customers worldwide with several proprietary hot section repairs that produce higher performance and extended life.

Details:

- Broaching

- Turning

- Hole making

- Edgebreak

- Inconel alloy

Engine Fan Rotor

Afterburner Components

Magellan Aerospace has a global reputation as a leading provider of maintenance services, afterburner component repair, and engine overhaul services to the world’s leading aerospace OEMs.

Contacts

John Bagan Business Development john.bagan@magellan.aero For more details about Frames and Cases

Dan Chaisson Business Development dan.chaisson@magellan.aero For more details about Turbine Components and Afterburner Components