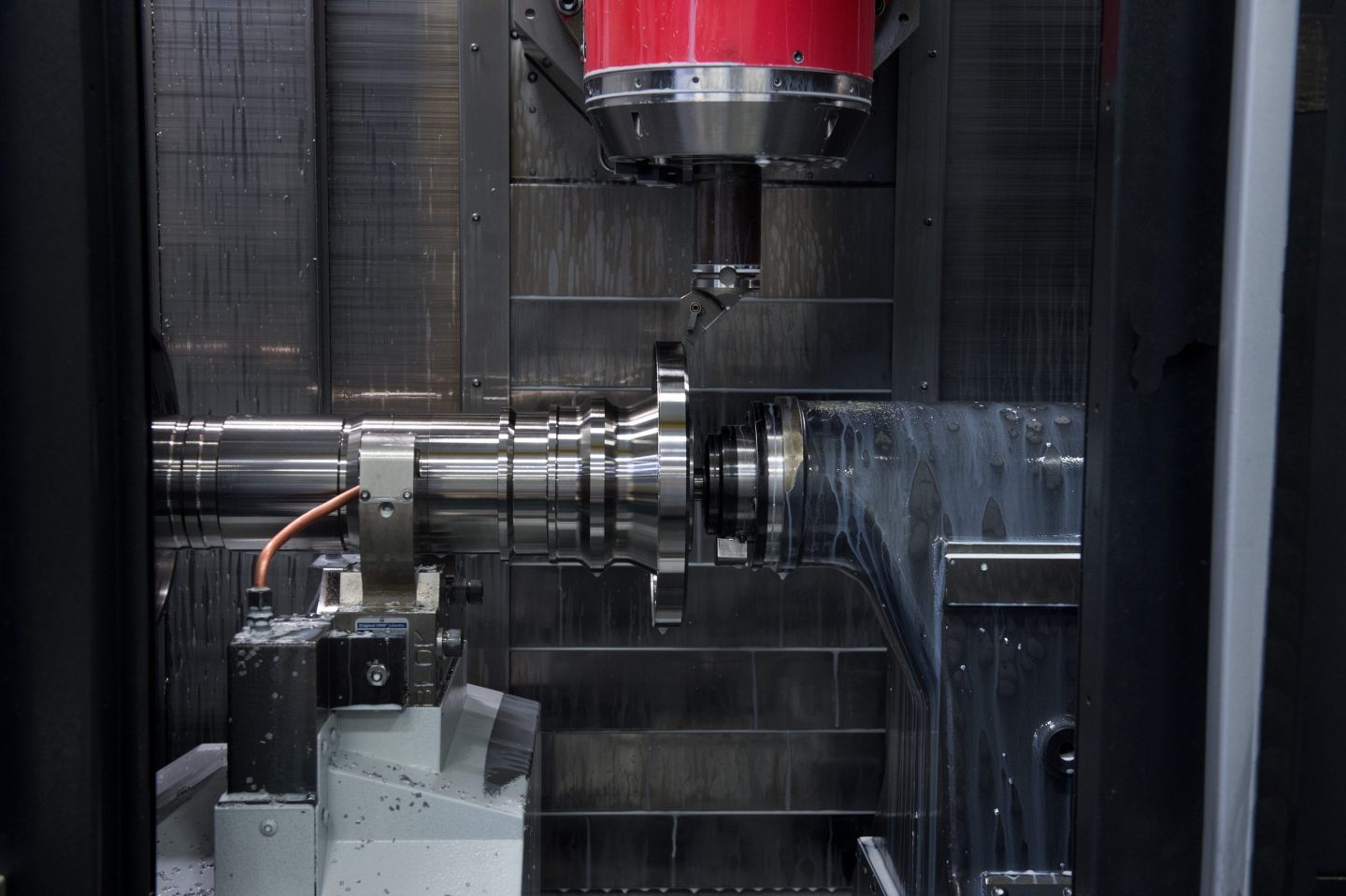

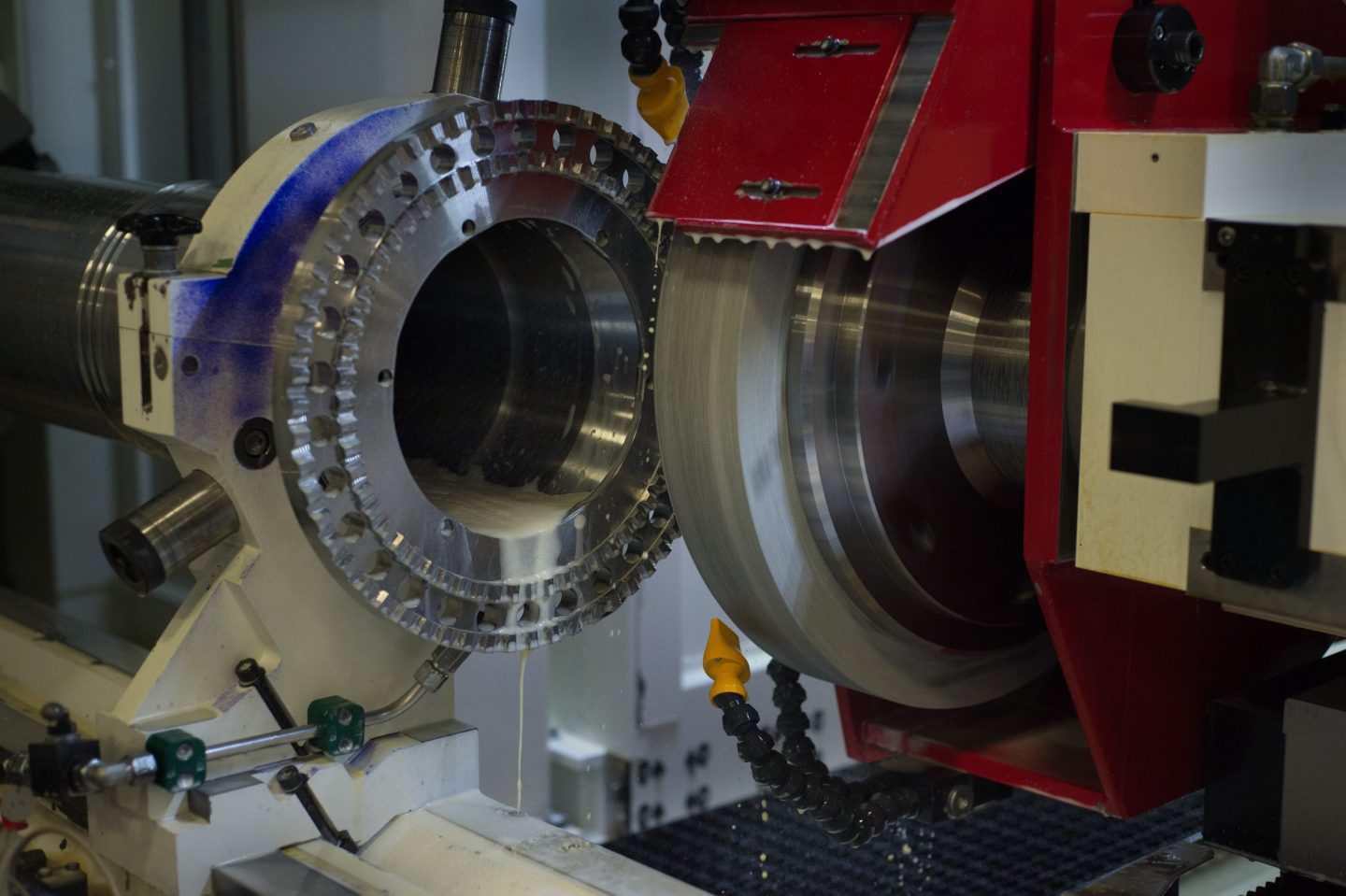

Magellan Aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers.

In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold sections of a gas turbine engine. Shafts up to 120 inches long and 30 inches diameter are machined and/or fabricated to very tight tolerances. They may be machined, electron beam welded, and/or inertia welded. Because we combine comprehensive end to end capability with the highest quality, our customers get what they need from one place with efficiency, value, and exceptional service.