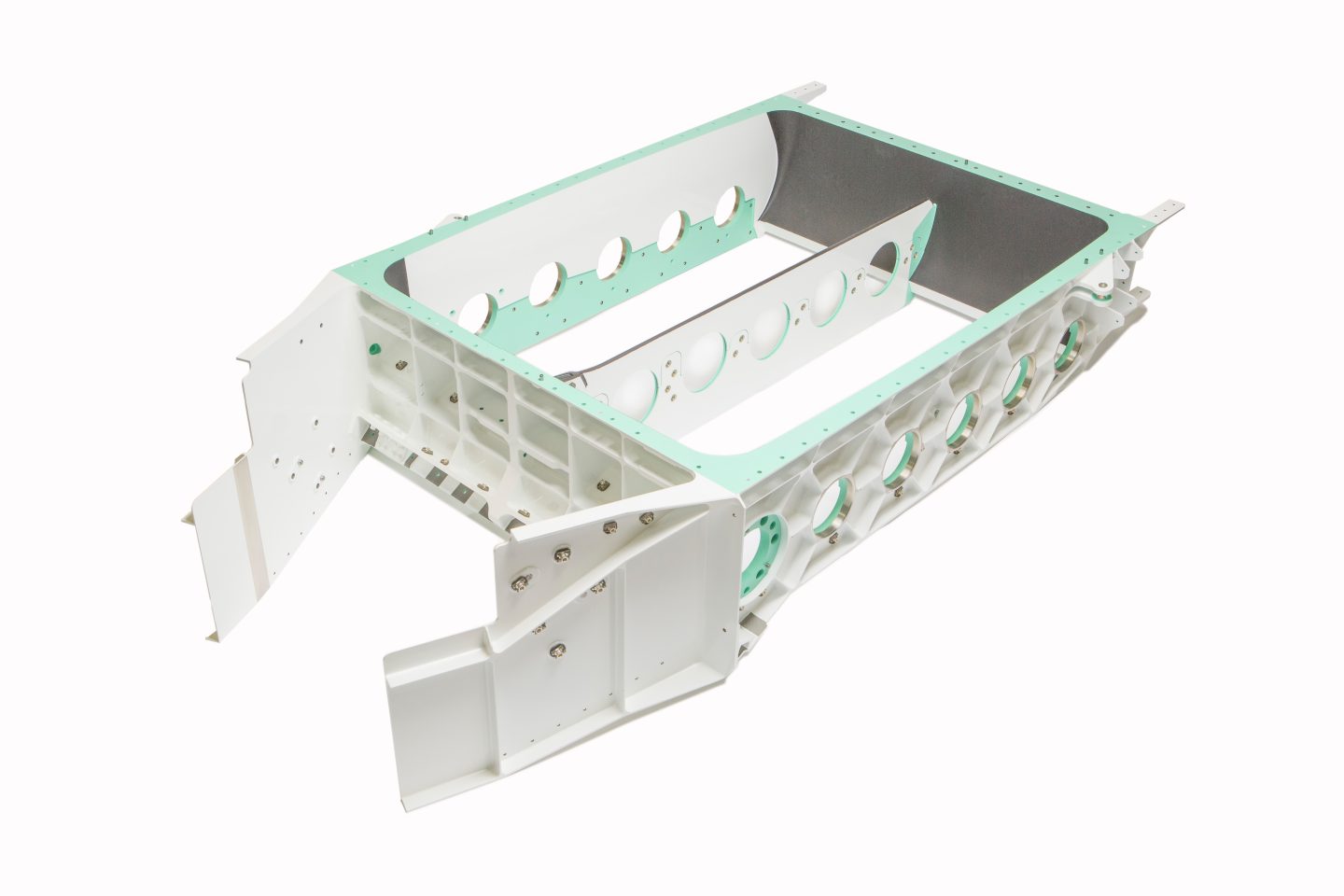

CROWN MODULES

Magellan is a leading global supplier of complete crown module assemblies for commercial aircraft.

Our crown module sub-assemblies are aluminum forged, machined and assembled to move seamlessly into an aircraft as a single whole assembly. They are designed for stress, functionality and customization. Each aircraft set consists of approximately 156 top level deliverable assemblies and hundreds of lower level detail components parts, most of which are manufactured by Magellan. Each of these assemblies fit in the crown of the fuselage sections to support the auxiliary trunking, ducting and cables above the cabin luggage bays.

Magellan’s consistently high level of technical support and commercial collaboration builds strong customer relationships based on a common goal: delivering a high quality product to point-of-use on time and on budget.

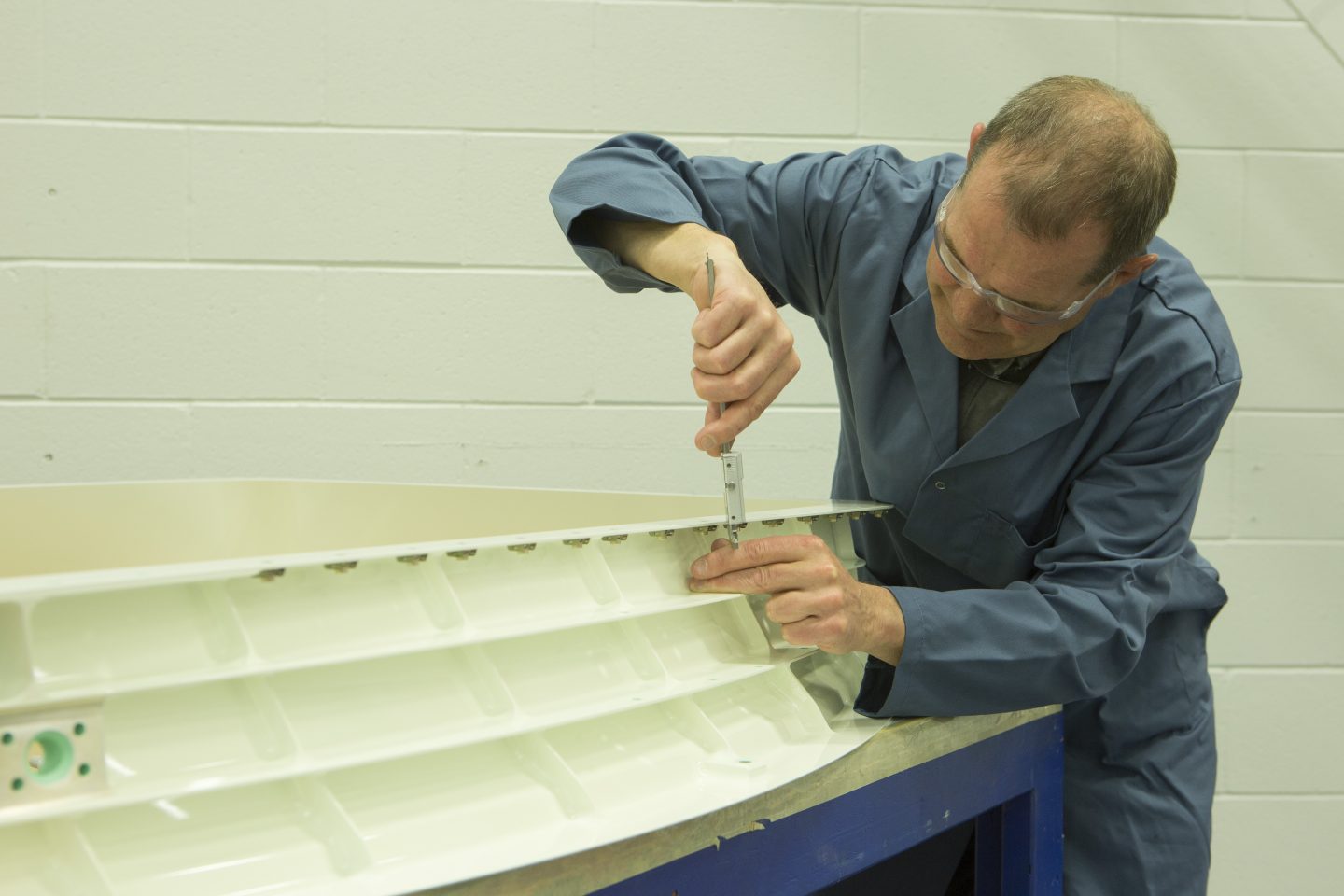

VANE BOX and TRANSITION DUCTS

Magellan manufactured VaneBoxes™ and transition ducts are produced for the short take-off and vertical landing aircraft variant of the F-35B. These assemblies are highly complex with flight critical structural components produced to very tight tolerances. They include three-dimensional complex flow path geometry required for the vertical lift fan module.

Complex details are machined and finished prior to the assembly process, which also requires machining operations of the assembly to complete. The entire manufacturing process is carried out in a self-contained, purpose-built manufacturing cell that is temperature controlled.

Manufacturing processes speak to Magellan’s high level of precision machining:

- 5-axis contour machining of flow path walls

- Post assembly machining operations with high sensitivity penetrant, chemical processing, and paint coatings

- High tolerance assembly machining (less than 0.001”)

- Fatigue and fracture critical structural component

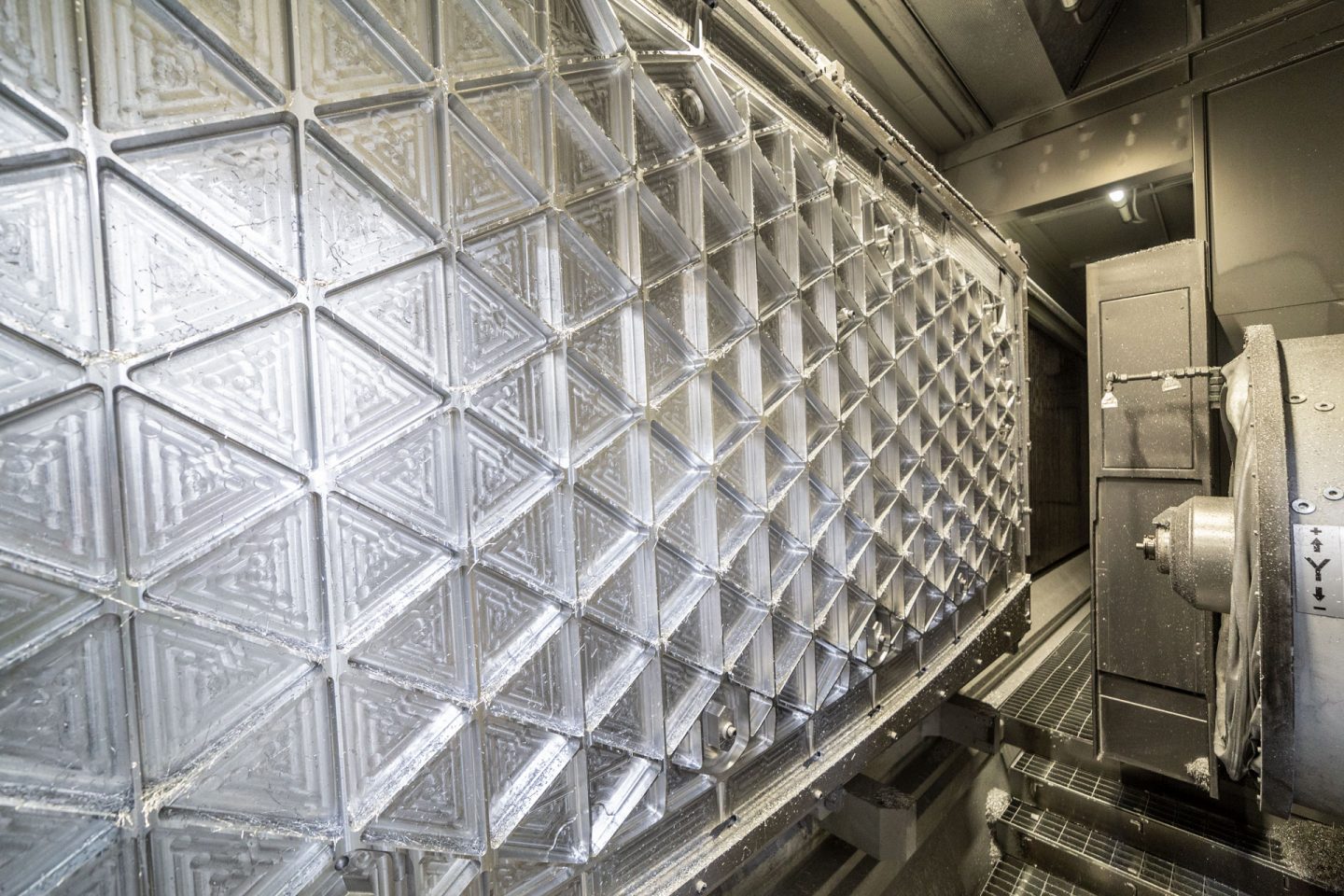

WING SPARS

Magellan has the capabilities to manufacture wing spars on a massive scale, both in size and volume.

Spars range from 10 meters to 22 meters in length with highly complex Magellan-manufactured parts. Fabricated on a high-speed long bed 5-axis milling machine, they’re composed of predominantly soft metals, a mix of aluminum and aluminum-lithium alloy. That means that while they’re lighter, they possess high tensile and yield strength to resist fatigue crack propagation.

Our full aluminum treatment capabilities are utilized for maximum quality surface treatment: Tartaric Sulphuric Anodise (TSA), heat treat, anodic flaw detect, dye penetrant flaw detect, and anodizing and paint.

CAPABILITIES:

- High volume soft metal removal using class leading long bed machining centres

- Multi-pallet 5-axis machining centres reducing both set-up and change over times

- Large multi-spindle machining gantry beds

- Efficient swarf collection and recycling systems active within operational facility

- Kits set supply and logistics management

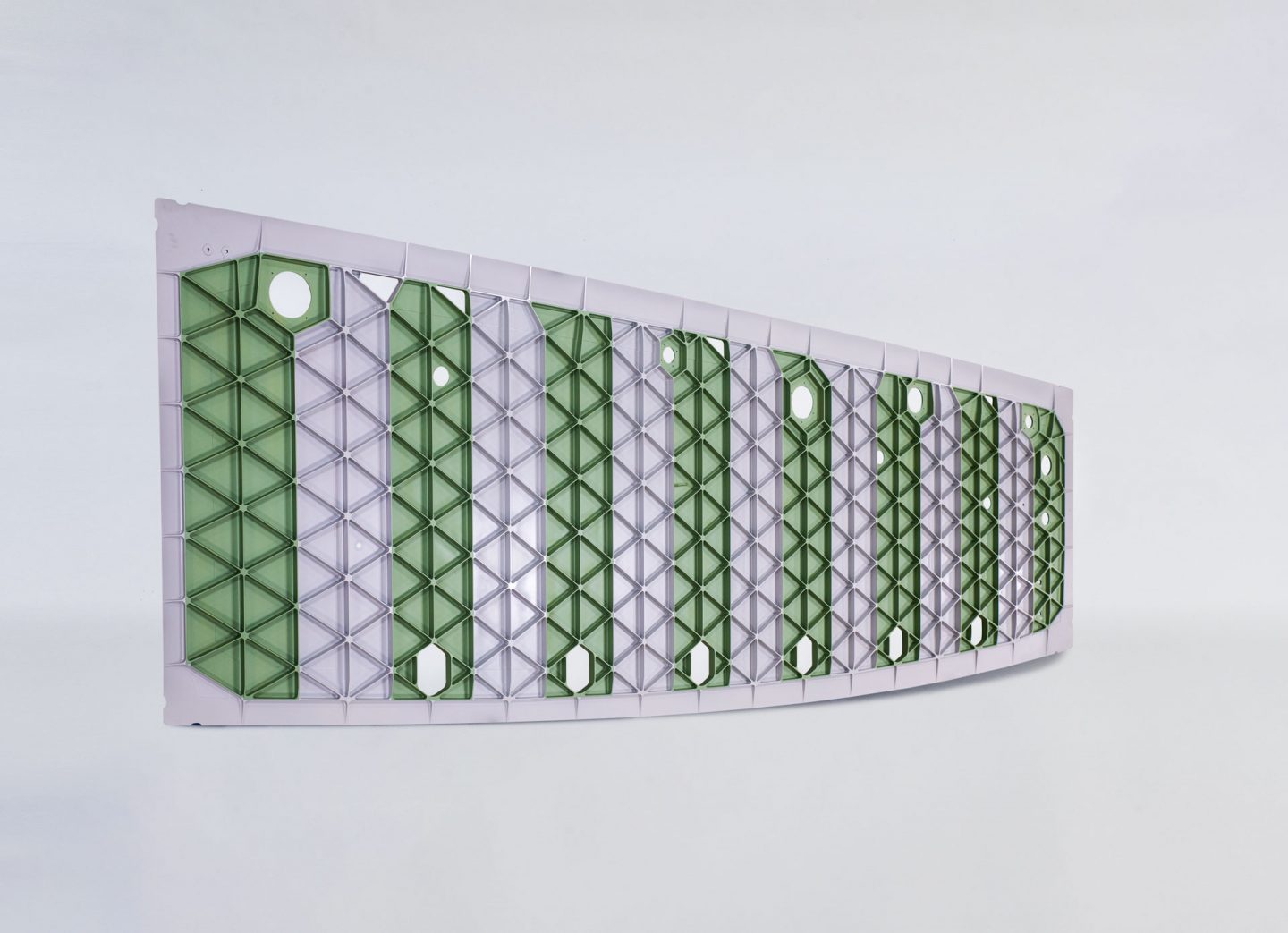

WING RIBS

Magellan’s integrated global supply chain supports high volume, soft metal manufacture of wing ribs for our global commercial and defense customer base. That is a large part of why we’re a highly competitive supplier. But what truly sets Magellan apart is investment in technology. Precision fabrication capabilities support manufacture of high tech, large scale components with milling machines over forty meters long producing a 0.1 mm tolerance. Our full aluminum treatment capabilities come into play here for maximum quality surface treatment: Tartaric Sulphuric Anodise (TSA), heat treatment, anodic flaw detect, dye penetrant flaw detect, anodizing and paint.

Magellan invites you to take a tour of our Bangalore facility. The plant specializes in high speed milling and turning of aerostructure components including commercial airplane wing ribs, edge beams, and details. Tour the facility.

CAPABILITIES:

- Comprehensive in-house engineering including CATIA V5 and VERICUT

- Zero point fixturing to ensure maximum OEE

- Flexible Manufacturing System (FMS) solution with 4 off 4-axis machines enabling lights out manufacturing

- Multiple machines capable of 3 to 5-axis-machining

- Comprehensive inspection including 4 CMMs Faro Arm HD scanning and sonar thickness measuring

- Treatments including anodising, chrome and CAD plating, PFD, and paint

WING SKINS AND access COVERS

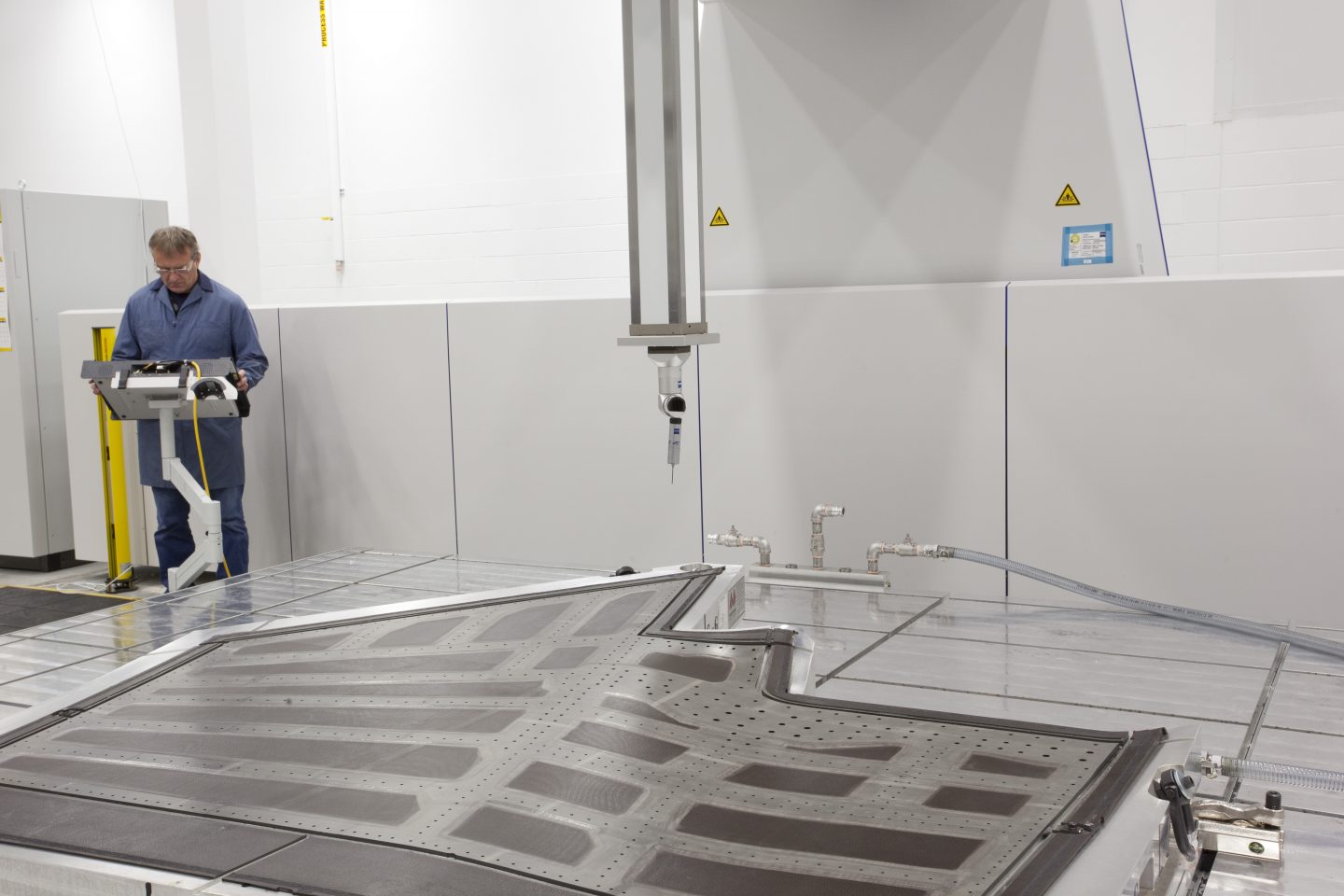

We are recognized for our expertise in high speed milling of composites to very exacting tolerances.

Magellan has been manufacturing and machining composites for many years. Our capabilities to produce increasingly complex product are expected to expand going forward as composite materials and their applications advance.

Wing skins and access covers are a direct product of this technological evolution. Composite components are manufactured to rigorous and demanding specifications. There is a requirement for 100%-inspected of each component which is performed using a state-of-the-art laser NDI technique. Flight and fracture critical composite skins are produced as part of the horizontal stabilizer assembly for the F-35 aircraft.

KITTING

Magellan’s kitting solutions provide point-of-use-kits to the industry’s leading OEMs.

They’re developed in close collaboration to meet exact specifications, arriving where and when our customers need them. Our dedicated team of purchasing, machinists, assembly technicians, inspectors, packers and shipping associates keep their finger on the pulse of every supplier for improved assembly efficiency, inventory control, and customer convenience.

-

Details:

- Vertical integration across Magellan divisions

- Kits up to more than 1000 components

- Robust procurement organization

- High and low rate programs

- CMI program for automatic replenishment of hardware triggered by a simple scan of a 2D barcode for immediate shipment

- Capability for minimum and maximum number of pieces to stabilize inventory

- Vendor Owned Inventory (VOI)

- Single point of contact for complex outsourcing projects