WING

CAPABILITIES:

- Design engineering including stress, F&DT and weights while holding delegated authority

- Complex CNC machining from medium to long bed up to 23 meters inclusive of high-speed milling 5-axis

- Detail fabrications and assemblies

- Largest independent surface treatments capability outside of UK OEMs

- 22-metre long chrome anodising tanks

- Sulphuric and hard anodising

- Paint finishing – oven cure to 25 metres

- Non-destructive testing – AFD, PFD, MFD, Hardness, Conductivity, Nital Etch

Magellan has earned a reputation as a leading supplier of commercial and defense aerospace wing assemblies for markets across the globe.

We’re one of the few suppliers in the world that operates at such a massive level of scale. Our facilities range in size and specialty, working strategically as an integrated global supply chain to manufacture, machine, treat, assemble and deliver wing components ranging from 2 meters to 22-metres in length. These include spars (front, medium, rear and intermediate), ribs, undercarriage components, reinforcing plates, access panels and flying control sub-assemblies.

Small Wing Components:

Wing ribs, small spars, access panels and prismatic components run up to 2 meters in length, and are made up predominantly of aluminum and aluminum lithium alloys.

- Comprehensive in-house engineering including CATIA V5 and VERICUT

- High volume, soft metal machining of complex components between 0.5m and 2m in length

- Including wing ribs and frames and sub-assembly

- Zero point fixturing to ensure maximum overall equipment effectiveness

- Flexible Manufacturing System (FMS) solution with multiple 4-axis machines enabling lights out manufacturing

- Multiple machines capable of 3 to 5-axis machining

- Comprehensive inspection including CMMs Faro Arm HD scanning and sonar thickness measuring

- Treatments including anodising, chrome and CAD plating, PFD, and paint

Medium-size Wing Components:

These are generally spars and ribs for the aircraft’s trailing edge, approximately 2 meters to 4.5 meters in length.

- High speed 5-axis milling machines with an envelope size 2m – 4m / soft metal

- Full engineering capability (programming)

- MasterCam, CATIA V5, VERICUT

- Commercial and defence (ITAR) portfolio

- CNC programs run without human intervention at 100% feed rates

- Minimum setups using single point loading/twin pallet machines providing high utilization

- Close working relationship / collaboration with external tooling companies and industry experts to maintain competitive advantage

- Kits set supply and logistics management

- CMM inspection up to 6m tables

Large Wing Components:

These range from 4.5 meters to the longest spar at 22 meters in length.

- High volume soft metal removal using class leading long bed machining centres

- Multi-pallet 5-axis machining centres reducing both set-up and change over times

- Large multi-spindle machining gantry beds

- Efficient swarf collection and recycling systems active within operational facility

- Kits set supply and logistics management full aluminum treatment capability including:

- Tartaric Sulphuric Anodise (TSA)

- Heat treatment

- Anodic flaw detect

- Dye penetrant flaw detect

- Anodise and paint up to 22m long

LANDING GEAR

Magellan’s landing gear components and kits are core products of our hard metal machining divisions, manufactured with precision tolerances to support specific requirements.

For our customers, it’s about trust. They rely on our capabilities as component integrators with a strong infrastructure, program and supply chain management. Operations are monitored regularly. We’re quick to address and adapt to customer needs while providing quality and performance at competitive rates and on-time delivery.

CAPABILITIES:

- Flexible Manufacturing System (FMS) machining centres focused on high equipment efficiency enabling machine utilization up to 95%

- In-process on machine probing of parts and tools for measurement and calibration

- In-house engineering and NC programming capability across multiple divisions, specializing in landing gear solutions

- Close working collaboration with external tooling and machine companies and access to industry experts for a competitive advantage

- Minimized fixture setups using Zero Point / quick changeover systems

- Standardized tooling shared between different parts for maximum flexibility and one-piece flow

- Integrated kitting solutions and logistics management

- Sub-assembly

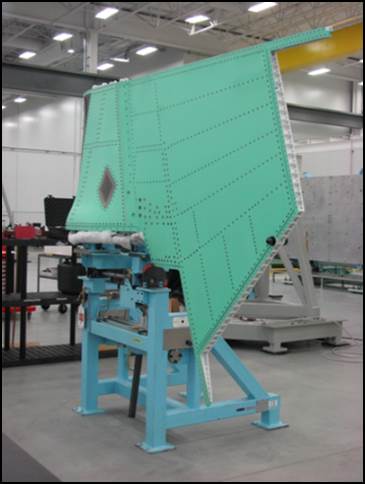

HORIZONTAL AND VERTICAL STABILIZERS

A truly integrated Magellan product, our horizontal and vertical stabilizers are the result of a company-wide effort. It begins with the manufacture of the detail components that make up the internal structure. Metallic details are machined at various Magellan facilities, and composite structural details are produced in our state-of-the-art Advanced Composite Manufacturing Centre. The detail elements are used to produce complete assemblies, which are then finished by installing electrical wiring, painted, and tested. A weight and balance check is performed on the final product before delivery.

FEATURES & CAPABILITIES:

- Climate controlled manufacturing environment 138,000 sq ft (temperature and humidity)

- Complex contoured fabrication

- Curing in 10’ x 36’ and 10’ x 30’ autoclaves

- Post-curing of laminates in dedicated ovens

- Flexible overhead gantry precision milling machines

- In-house composite testing

- Integrated manufacturing from the model using FiberSIM for both cloth cutting and laser projection

- Laser NDI

- Clean room EXPLORE MAGELLAN! Tour of Clean Room

-

-

NACELLE EXHAUST SYSTEMS

Magellan has extensive experience in the design, manufacture, and certification of nacelle exhaust systems.

Our experience demonstrates a lineage of programs where we have collaborated with our customers to supply unique exhaust systems for engines on different aircraft platforms. It all starts with our conceptual designs and front end engagements where we can bring our experiences and knowledge to the program. Magellan is able to create unique solutions for our customers requirements applying our engineering experience and tools allow us to have a and tools in combination with our strong design to cost approach.

CAPABILITIES:

- Design and build of exhaust systems – acoustic and non-acoustic

- Metal joining – various welding, brazing, and adhesive bonding

- Chemical processing

- Heat treatment (vacuum and atmospheric)

- Conventional and non-conventional machining

- Complex assembly

- Honeycomb manufacturing

Our nacelle exhaust products are fabricated assemblies predominantly in titanium and nickel alloys with acoustic and non-acoustic treatments. For our acoustic products, we utilize internally manufactured metallic laser welded honeycomb. All of our fabricated exhaust structures combine a number of different processes including machining, bulge forming/expansion forming, flow/shear forming, welding, heat treatment, and a robust assembly processes.