3D Sand Printing

Applying 3D printing technology to the sand casting process allows Magellan to manufacture complex sand cores and molds directly from CAD data, eliminating the need for hard tooling in certain cases, such as for prototypes. For production applications, low cost hybrid tool options are most cost effective. 3D sand printing technology yields highly accurate and repeatable results with the flexibility to easily accommodate customer design changes.

Simulated Metal Pouring and Solidification Modeling

Using the latest in metal simulation software, Magellan is able to accurately predict casting quality before investing significant time and resources into metal pouring trials. This means a shortened overall lead time to develop a new program and a more robust metallurgical process for serial production.

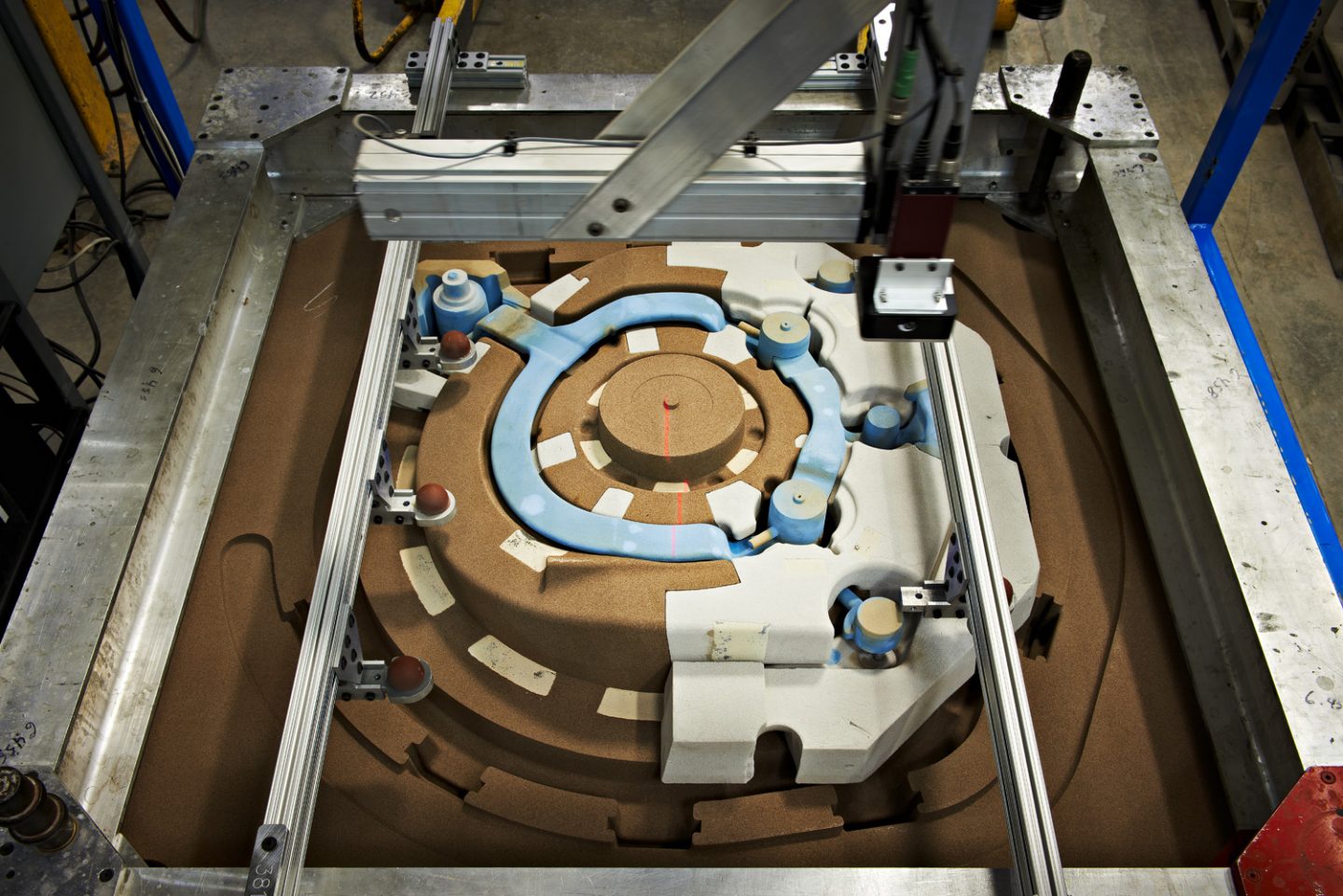

Automated Pouring

Once metal simulations are optimized, controlled pouring of the molten metal is critical to the metallurgical integrity of each casting. Our advanced automated pouring equipment tightly controls pouring process variables to achieve superior, part-to-part results.

Automated Finishing

Incorporating automated equipment such as CNC machining centres into the finishing process improves overall dimensional control and part consistency, and helps ensure zero process-generated defects.

Digital Radiography

Automated digital radiography provides for the rapid capture of high resolution radiographic images of castings, eliminating conventional x-ray film processes.

3D Scanning

Digital scanning is used at key stages of the casting operation to provide critical process control monitoring and to help ensure castings are fully compliant to drawing requirements.